Process Development & Scale-Up

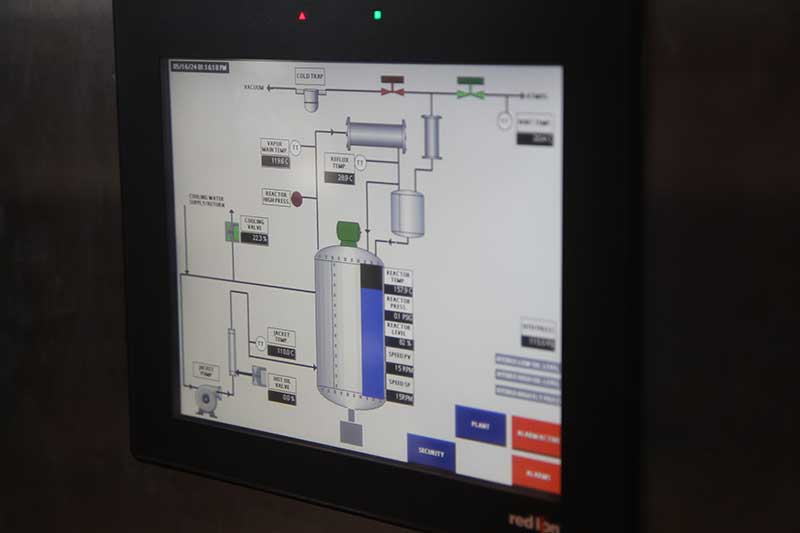

InChem’s dedicated technical team has a proven track record of successfully transitioning processes from pilot to commercial scale. Our scale-up and development projects are overseen by a PhD chemist with years of experience in process development and scale-up. Customers are encouraged to come on site and participate in trials. Which allows for much closer collaboration between technical teams. It also helps provide customers with the Transparent service they have come to expect from us.

Following a trial, InChem’s technical team will generate a post-trial report which provided detailed information about:

- Process parameters

- In-process and full final quality results

- Process yields

- Recommendations for future batches.