Equipment - Batch Reactors

Our batch reactors are designed to handle a wide variety of chemical processes. The entire production area is Class I Div II, allowing us to handle flammable, toxic, and corrosive materials. The equipment is generally 316ss (our K4 reactors system is constructed of 304ss) which allows for compatibility with a wide variety of chemicals. All of our reactors are pressure and vacuum capable. The specific ratings of each vessel vary, but generally speaking, we can handle pressures up to 70 psig, and can pull vacuum down to approximately 28 In Hg. Each vessel is also equipped with condensers, allowing us to run at full take-off, or reflux distillate back into the vessel. We also have a variety of agitation profiles to suit your process needs. Two of our commercial scale reactors have helical agitators with 75 HP hydraulic drives. Allowing them to agitate materials up to approximately 1,000,000 cps. All our vessels are controlled via PLC with a data historian. Our equipment is designed to be flexible, and we do modify equipment to meet customer requirements regularly. If you want to find out if your process fits well in our existing asset base please ‘contact us here’.

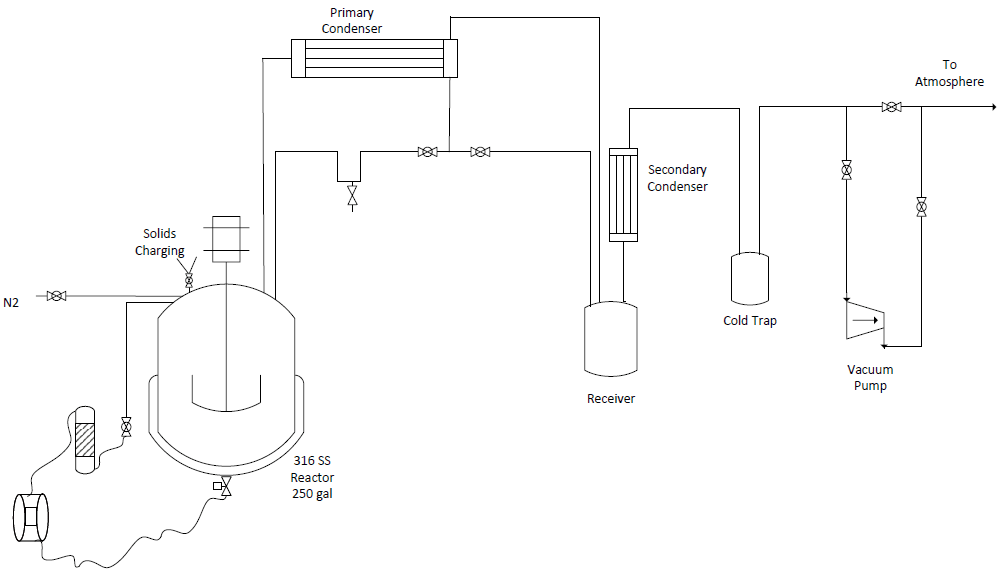

250-Gal

- “The 250” is a 250-gallon reactor constructed out of 316ss for compatibility with a wide variety of chemistries.

- The jacket is heated by tempered water or steam and can reach temperatures as high as 180C.

- The maximum operating pressure is 90psig.

- The 250 can pull full vacuum (approx. 28 in Hg) and the overheads are set up to allow for full take-off or reflux.

- The hydraulically driven helical agitator is well suited for high viscosity applications.

- Controlled via PLC

K1

- “The 250” is a 250-gallon reactor constructed out of 316ss for compatibility with a wide variety of chemistries.

- The jacket is heated by tempered water or steam and can reach temperatures as high as 180C.

- The maximum operating pressure is 90psig.

- The 250 can pull full vacuum (approx. 28 in Hg) and the overheads are set up to allow for full take-off or reflux.

- The hydraulically driven helical agitator is well suited for high viscosity applications.

- Controlled via PLC

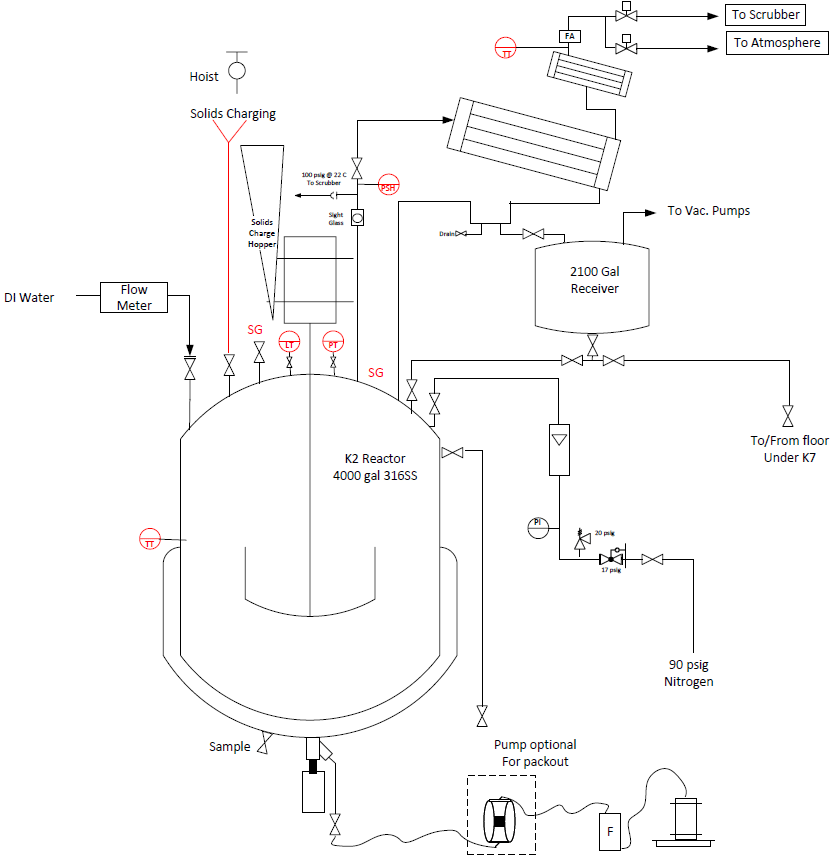

K2

- K2 is a 4,000-gallon reactor constructed of 316ss for compatibility with a wide variety of chemistries.

- The jacket is heated with tempered water or steam and can reach temperatures as high as 180C.

- It is rated for a maximum operating pressure of 100psig.

- K2 can pull a full vacuum (approx. 28 in Hg) and the overheads are set up to allow for full take-off or reflux.

- The agitator has 2 sets of pitched turbine blades connected to a variable speed agitator motor making this unit suitable for mixing liquids.

- A solids charging chute allows us to charge solids from bags or supersacks.

- Controlled via PLC

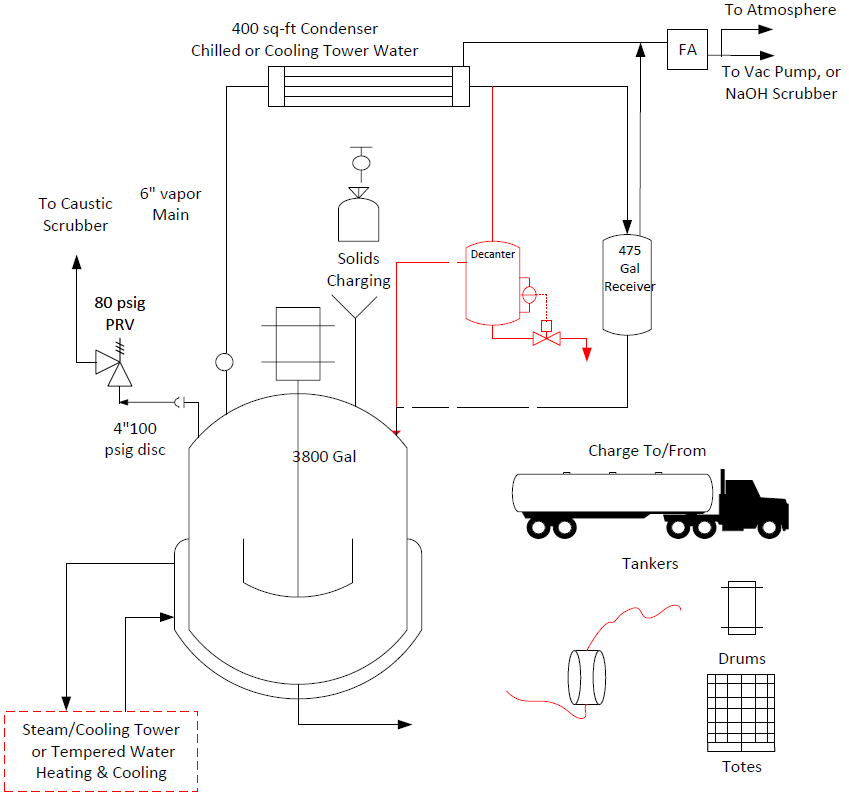

K3

- K3 is a 3,800-gallon reactor constructed of 316ss for compatibility with a wide variety of chemistries.

- The jacket is heated with hot oil and can reach temperatures as high as 285C.

- The double mechanical agitator seal allows this unit to run at pressures up to 75psig.

- K3 can pull a full vacuum (approx. 28 in Hg) and the overheads are set up to allow for full take-off or reflux.

- The agitator has 3 sets of pitched turbine blades and is connected to a variable speed agitator motor making this unit suitable for mixing liquids.

- A solids charging chute allows us to charge solids from bags or supersacks.

- Controlled via PLC

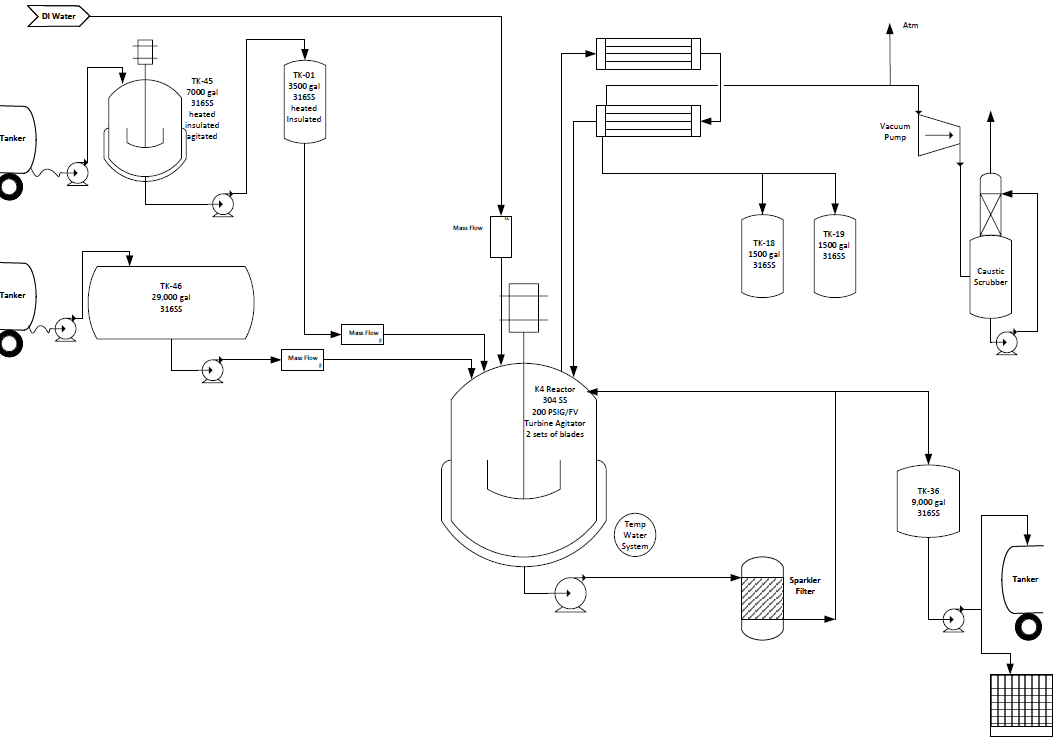

K4

- 6,000 gallon reactor constructed of 304ss

- The jacketed is heated with tempered water or live steam to reach temperatures as high as 180C

- Double mechanical agitator allows for pressures up to 75psig

- Vacuum to approximately 28 in Hg

- Overheads set up for reflux or full take-off

- Two sets of turbine agitator blades are suitable for mixing liquids

- Internal coils for heating or cooling

- Heated and agitated pre-mix tanks

- Controlled via PLC

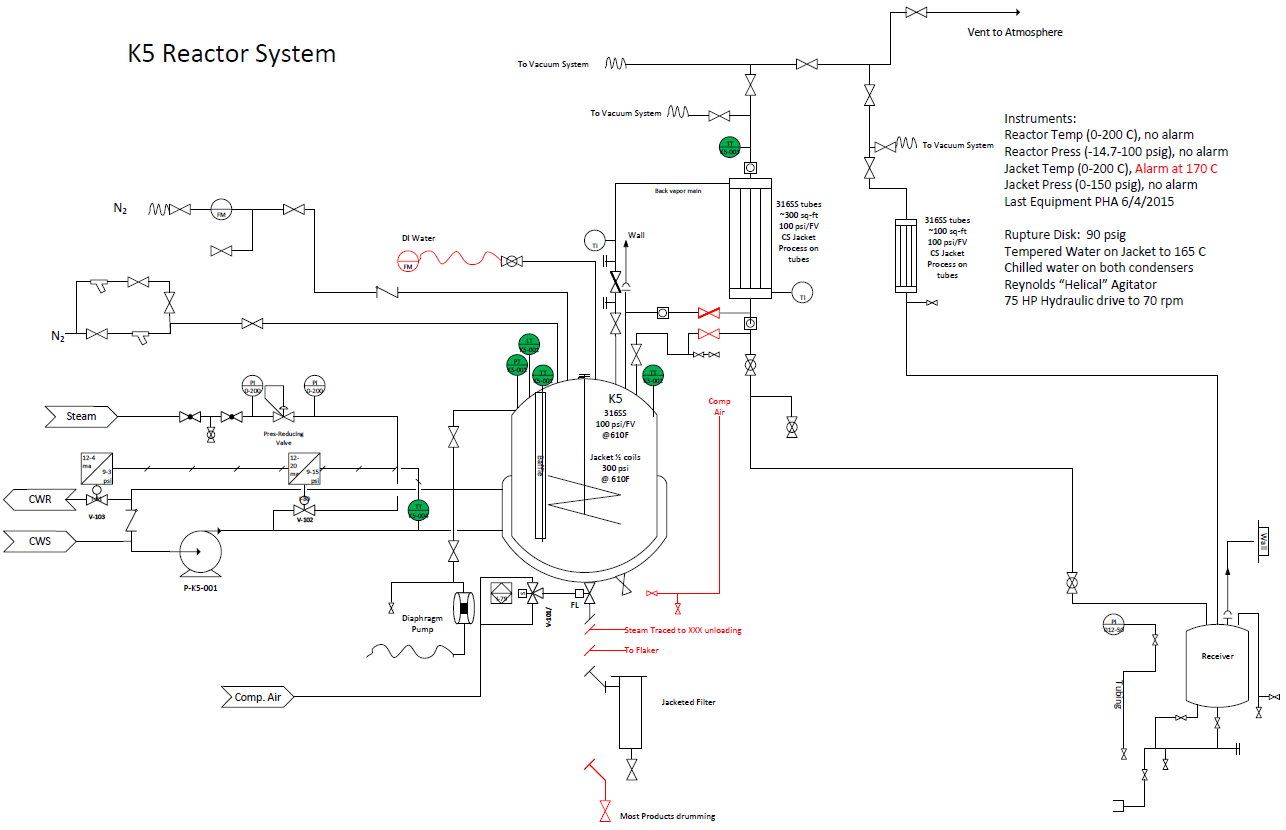

K5

- K5 is an 1,800-gallon reactor constructed of 316ss for compatibility with a wide variety of chemistries.

- The jacket is heated with tempered water or steam and can reach temperatures as high as 180C.

- It is rated for a maximum operating pressure of 90psig.

- K5 can pull full vacuum (approx. 28 in Hg) and the overheads are set up to allow for full take-off or reflux.

- The helical agitator is connected to a 75hp hydraulic drive agitator motor allowing K5 to agitate products up to 1,000,000 cps.

- It is also able to be piped directly to our flaker belt.

- Controlled via PLC

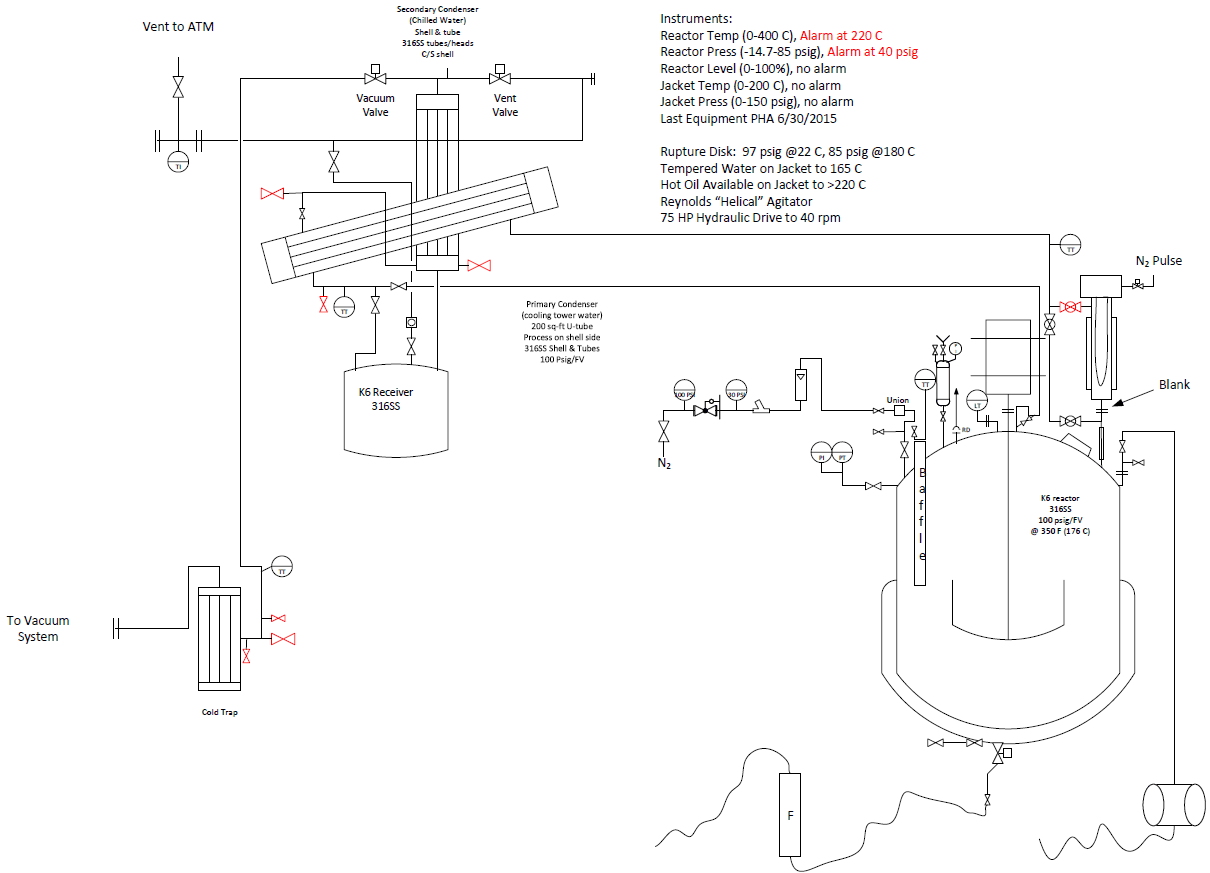

K6

- K6 is a 2,800-gallon reactor constructed of 316ss for compatibility with a wide variety of chemistries.

- The jacket is heated with hot oil and can reach temperatures as high as 285C.

- It is rated for a max operating pressure of 40psig.

- K6 can pull full vacuum (approx. 28 in Hg) and the overheads are se tup to allow for full take-off or reflux.

- The helical agitator is connected to a 75hp hydraulic drive agitator motor allowing it to agitate products up to 1,000,000 cps.

- It is also able to be piped directly to our flaker belt.

- Controlled via PLC

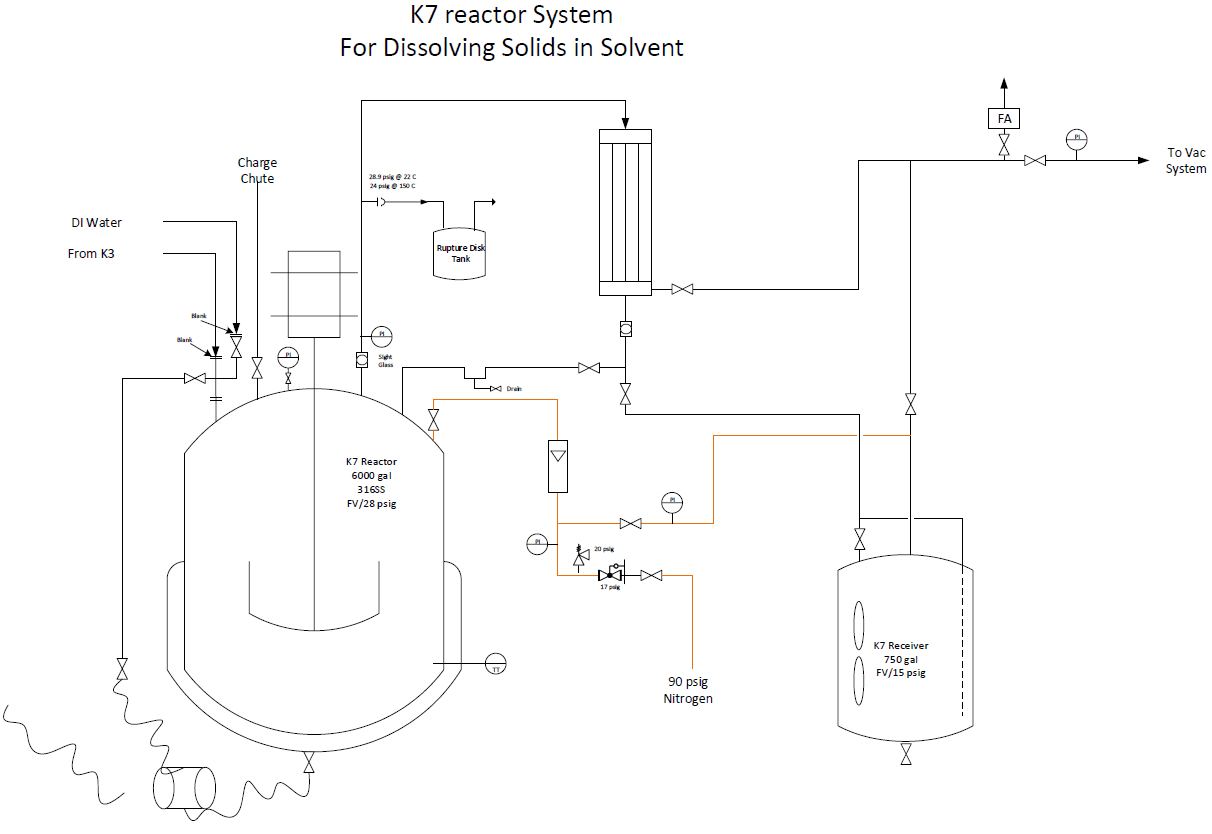

K7

- K7 is a 6,000-gallon reactor constructed of 316ss for compatibility with a wide variety of chemistries.

- Its size allows it to produce a full tank truck of product in a single batch.

- The jacket is heated with tempered water or live steam and can reach temperatures as high as 170C.

- It is rated for a max operating pressure of 25psig.

- K7 can pull vacuum (approx. 28 in Hg) and the overheads are set up to allow for full take off or reflux.

- The agitator has pitched turbine blades and is suitable for mixing liquids.

- Controlled via PLC