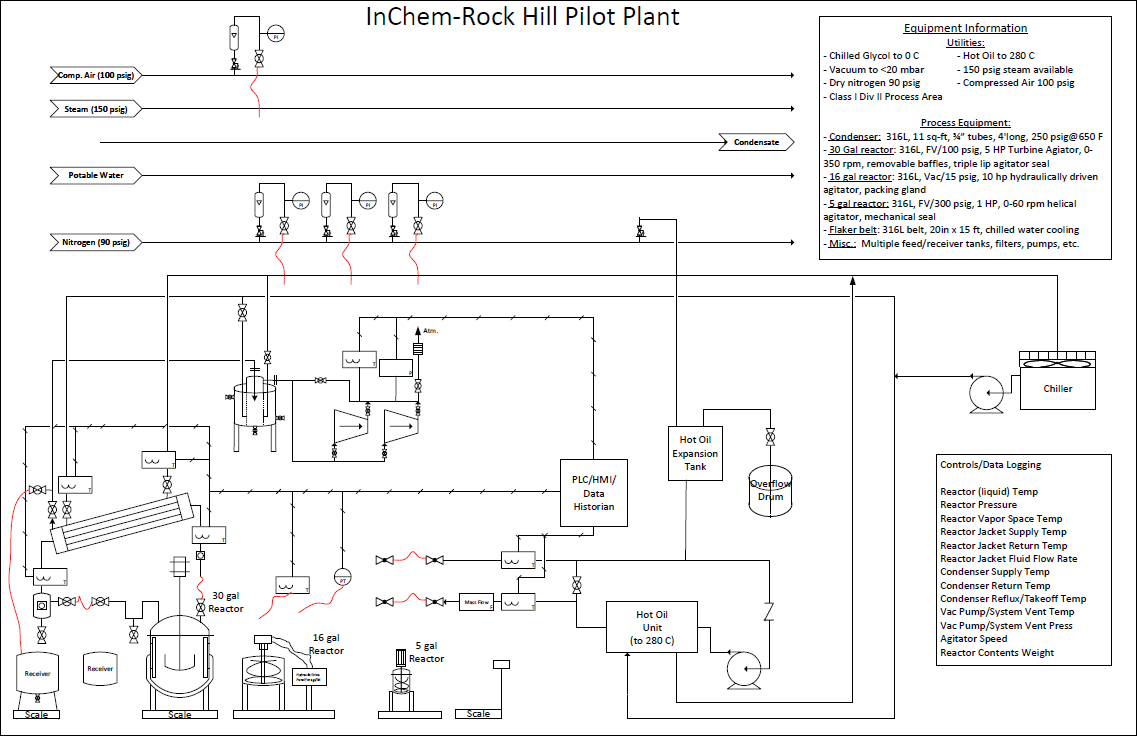

Equipment - Pilot Plant

InChem’s pilot plant is designed for compatibility with a wide variety of chemical processes. The entire pilot plant area is Class I Div II allowing us to handle flammable, corrosive, and toxic materials. Multiple skid-mounted vessels allow us to swap assets in and out to produce at various scales, and with varying agitation profiles (turbine blades or helical mixers). All pilot scale reactors are on weigh scales to ensure charge weights are correct. The pilot units are pressure and vacuum capable, with condensers and receivers that can be set to full take-off, or reflux. The entire unit is controlled via PLC, which is hooked up to a data historian. This set up allows us to pull relevant process data (temp, pressure, agitator amp draw, etc) and include it in the post-trial report. Both units are heated via hot oil and can reach temperatures up to 285C. The 30-gallon unit can operate at pressrues up to 45PSIg, and the agitation profile is suitable for liquid processes. The 50-gallon unit has a helical agitator and in addition to being able to reach pressures of 45PSIg, can also agitate materials up to 500,000 cps.

30 Gallon

- Can operate at a maximum pressure of 45PSIG. The paddle agitators are suitable for liquid processes.

- Hot oil jacket up to 285C

- Hot oil jacket up to 285C

- Controlled via PLC

With the capability to operate at a maximum pressure of 45PSIG, our paddle agitators are the perfect choice for liquid processes. The hot oil jacket can reach temperatures of up to 285C, ensuring efficient heating for your operations. The unit is controlled via PLC, with process data logged by the data historian.

50 Gallon

- Can operate at a maximum pressure of 45PSIG. The helical agitator and hydraulic drive motor are capable of handling products up to 500,000 cps.

- Hot oil jacket up to 285C

- Controlled via PLC

Capable of operating at a maximum pressure of 45PSIG, this cutting-edge equipment features a helical agitator and hydraulic drive motor that can effortlessly handle products with viscosities of up to 500,000 cps. With a hot oil jacket that can reach temperatures of up to 285C, it is designed to meet the most demanding industrial needs. The unit is controlled via PLC, with process data logged by the data historian.