InChem News

Why Contract Manufacturing is the Way to Go in Chemical Mixing and Blending

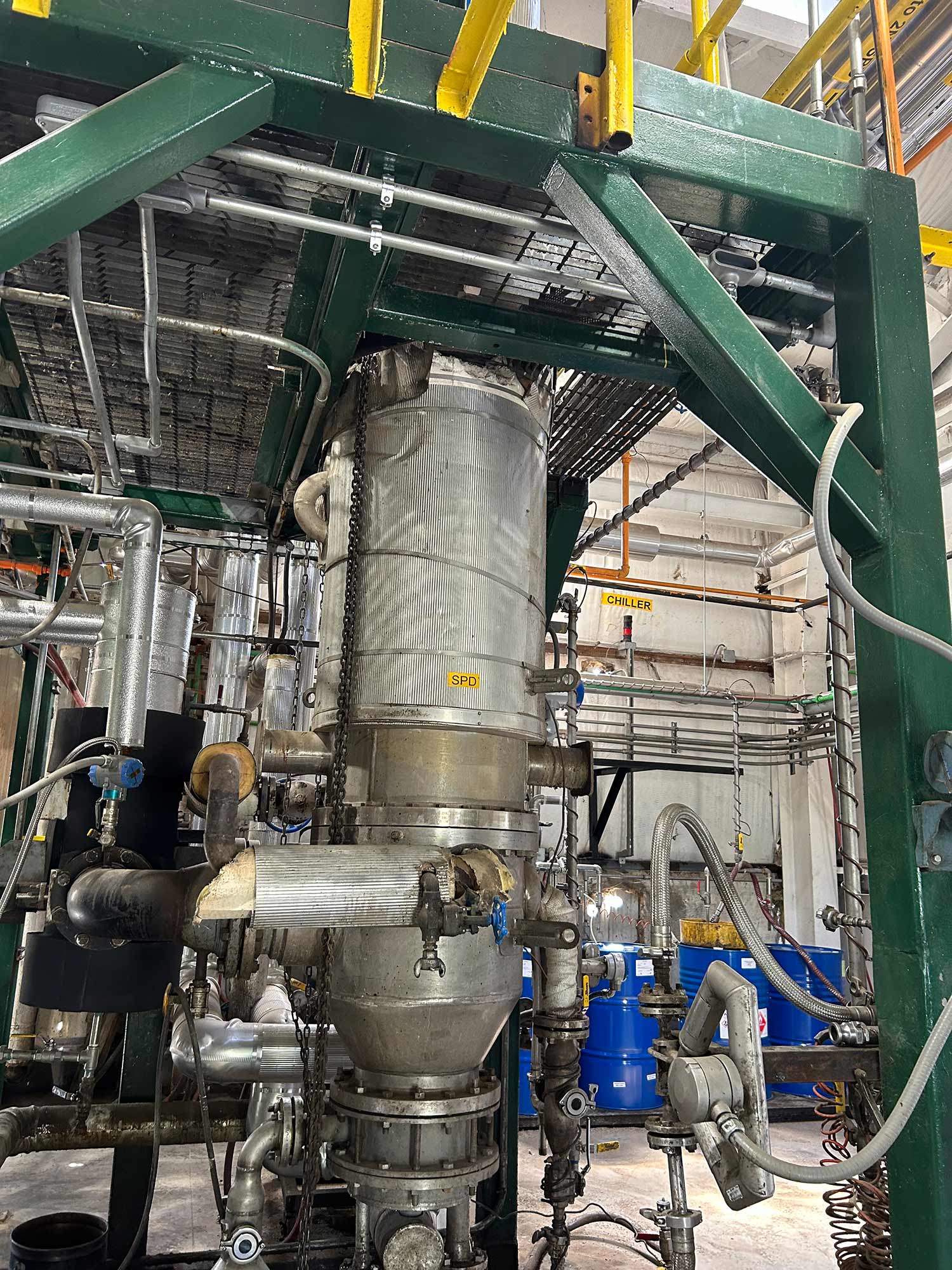

Wiped film distillation is a process technology that is particularly useful when dealing with heat-sensitive and high-boiling point compounds. A wiped film evaporator (WFE) consists of a vertical cylindrical evaporator body that utilizes a rotor, that turns at a variable speed, to wipe the feed liquid into a thin film on to the internal heated surface of the evaporator. The feed liquid is fed near the top of the cylinder. Temperature and reduced pressures are applied inside the unit to help evaporate volatile compounds.

Introduction: Separating Compounds with Heat & Reduced Pressure

Traditional distillation methods, relying on bulk boiling and condensation, can fail to meet quality requirements when processing materials containing thermally unstable or high-boiling components. These methods can lead to product degradation, polymerization, unwanted color generation, and significant losses in product quality. Wiped film distillation offers an alternative solution that allows for the separation of various compounds without subjecting the material to long periods at high temperatures.

Understanding the Fundamentals: How Wiped Film Distillation Works

Wiped film evaporators have a few main components. A vertical cylinder equipped with an internal rotor. This rotor houses wiper blades, which are crucial for creating a thin, constantly renewed film of the feed liquid on the heated inner surface of the evaporator. The unit is designed to fulfill 5 primary functions.

- Feeding and Distribution: The feed liquid is introduced to the evaporator and distributed evenly onto the heated surface.

- Film Formation: The rotating wiper blades create a thin, uniform film of the liquid, maximizing the surface area exposed to heat and vacuum.

- Evaporation: The heated surface provides the energy required for the volatile components of the feed to evaporate.

- Condensation: The vaporized components travel a short distance to a condenser, where they are cooled and condensed. Some wiped film distillation units will have a condenser mounted inside the rotors, while other units will have an externally mounted condenser. The location of the condenser does not fundamentally change how the unit works.

- Collection: The condensed distillate and the remaining residue are collected separately. The finished product may be the distillate or the residue.

Primary Advantages of Wiped Film Distillation:

- Very Deep Vacuum: Low Pressure = Lower Operating Temperature

- The ability to operate under an exceptionally deep vacuum, often in the range of 0.5 mbar.

- This deep vacuum significantly reduces the boiling points of the components in the mixture, allowing for evaporation at lower temperatures. Lowering the heat history reduces the risk of thermal degradation, color generation, or unwanted polymerization.

- Low Residence Time: Minimizing Thermal Exposure

- Wiping a thin film of product around the inside of the unit significantly increases the surface area, allowing for faster and more efficient devolatilization.

- Wiped film evaporators operate as a continuous process, so only a small amount of material is inside the unit at any given time.

- This minimized exposure to heat significantly reduces the risk of thermal degradation.

- The rapid movement of the thin film helps to prevent the formation of hot spots, which can lead to localized degradation and inconsistent finished product quality.

- InChem’s 2m2 wiped film evaporator typically has residence times of 12-15 seconds.

- Limited Heat History: Protecting Delicate Compounds

- The combination of lower operating temperatures and shorter residence times means products are subjected to significantly lower heat history.

- Products are much less likely to experience thermal degradation.

- The reduced heat history also minimizes the formation of unwanted byproducts, leading to a higher purity final product.

Multiple Applications

This process technology is used in a variety of industries.

- Chemicals: Separation of high-boiling point solvents, purification of polymers, and recovery of valuable byproducts.

- Petrochemicals: Purification of lubricating oils, recovery of used oils, and separation of high-boiling point fractions.

- cGMP Products: Deodorization and concentration of flavors and aromas, purification of edible oils, and removal of pesticides.

Equipment and Operational Considerations

Wiped film distillation systems are available in various configurations, ranging from laboratory-scale units to large-scale industrial plants. Key operational considerations include:

- Evaporator Design: The choice of evaporator design, including the type of rotor and wiper blades, is crucial for achieving the desired final specifications of your product.

- Vacuum System: A high-quality vacuum system is essential for consistently maintaining the desired operating pressure.

- Heating System: Precise temperature control is critical for ensuring efficient evaporation and minimizing thermal degradation. Ensuring you do not put too much heat into the system will limit the likelihood of over stripping a product and unintentionally separating unwanted compounds from the feed stream.

- Length of Vapor Path: The location of the condenser will impact the distance vapors travel before entering the condenser. Short path distillation units (SPD’s) have a condenser located inside the unit. This shortens the vapor path and improves the vacuum capability of the unit. Units with external condensers have a longer vapor path, and therefore, are unable to pull as deep of a vacuum.

Challenges and Limitations

Wiped film distillation offers significant advantages, but like all process technologies, it is not a one size fit all solution. There are limitations that need to be considered.

- Viscosity: Highly viscous feeds can be challenging to process. InChem’s wiped film distillation units can handle materials with a maximum viscosity of approximately 12-15k cps at operating temperatures.

- Fouling: The formation of deposits on the heated surface can reduce efficiency.

- Scale-up: Scaling up from laboratory to industrial scale can be challenging. Small glass units may not provide all the process data needed for effective scale up. Ensuring that you account for changes in the internal geometry, the material of construction, heating medium (steam, oil, etc.) and heat transfer across the unit are essential for a successful scale up. InChem’s pilot wiped film evaporators have been installed with this in mind and the data generated from processing half a drum of feedstock will typically tell us everything we need to know to scale to commercial volumes.

Conclusion: A Useful Tool

Wiped film distillation is an ideal candidate to process a wide variety of chemical feedstocks. The nature of this process technology allows InChem to purify compounds that cannot be properly purified in a traditional distillation process.

Contact InChem today for more information about how our wiped film distillation units can service your toll chemical manufacturing needs.

For over 30 years, InChem has been a leading supplier of Chemical Toll Manufacturing services. Our operational philosophy is centered around providing Responsive, Transparent, and Flexible Service. We are committed to providing our customers with a toll manufacturing partner that they can trust to handle their IP securely and confidentially. We require that all products produced at InChem are managed in a way that meets or exceeds the best practices in the industry. 100% of our business is chemical toll manufacturing which means we can guarantee that we do not compete with our customers in the marketplace.

In general, our chemical manufacturing assets are compatible with chemistries that meet the following requirements:

- Are compatible with 316ss

- Require temperatures between 25C and 285C

- Require pressures less than 75PSIg

- Have a viscosity of less than 1,000,000 cps

- Do not require RMP

- Are not pyrophoric

Our wiped film distillation assets are capable of processing materials at the following parameters

- Temperatures up to 285C

- Deepest attainable vacuum at the pilot scale is 0.05mbar

- Deepest attainable vacuum at the commercial scale is 0.5mbar

We have batch reaction capability from the pilot scale (5-gallon to 50-gallon reactors), and commercial scale (from 250-gallon to 6,000 gallon reactors). We also have wiped film distillation capability at the pilot and commercial scale. We are capable of handling pails, drums, IBC’s, bulk, and isotainers. We do not have access to rail siding.

Contact InChem for your toll chemical manufacturing needs.